- Products

- Robotic Bending Cell

- Customized production line

- LAG Press Brake

- Fastener Insertion machine

- Rainer Punch Press

Home

>

Products

>

Customized production line

Home

>

Products

>

Customized production line

021-3900-3785

021-3900-3785

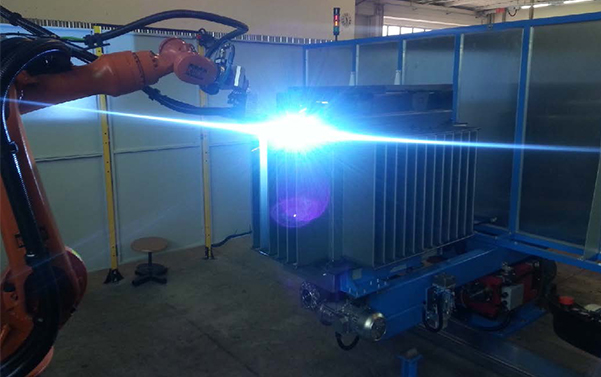

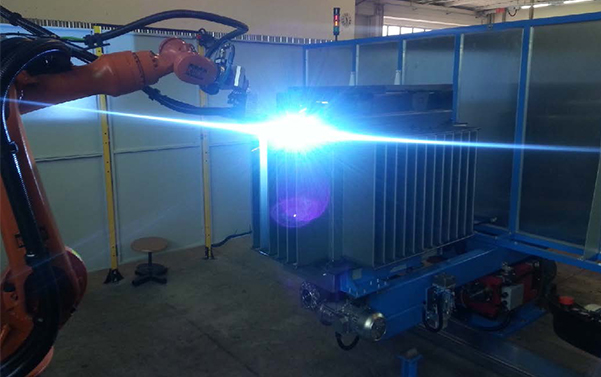

Automation of Welding

Returns a list of

Returns a list of

LAG detects the status of the manufacturing work piece in CNC system at any time in remote manner by utilizing the visual monitoring system and reduces the welding pollution furthest by utilizing the dust-removing equipment.

The details show

Detailed parameters

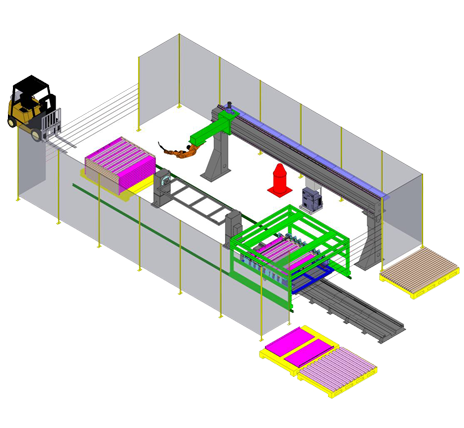

Unmanned welding workshop

LAG detects the status of the manufacturing work piece in CNC system at any time in remote manner by utilizing the visual monitoring system and reduces the welding pollution furthest by utilizing the dust removal equipment.

Visual monitoring and calibration system

It can monitor the welding work piece status remotely to master the real-time dynamic status at any time.

The laser scanner on the welding manipulator can scan two positions on electrically-welded structure to determine the welding path and correct the welding path of welding gun based on the signal from scanner. The control system receives the identification signal and leads the manipulator to trace the scanning path with the laser scanner installed on the manipulator as per the size, thus making the welding gun implement the welding task completely.

Dust removal system

The high negative pressure dust collection device with the estimated standard is adopted to capture the submicron order welding fume and grain generated in the welding process for the purpose of reaching the indoor discharge standard.

Welding manipulator

Manipulator conducts the high-accuracy movement along the rail through the cantilever servo guide rail or walking type ground rail under the action of transmission structure of the high-precision servo motor driving wheel gear rack to reach at the welding station for operation. 7-axis manipulator can contact the surface of welding work piece at the greatest extent by coordinating with the positioner to complete welding.

Positioner

The servo turnover mechanism is driven by the servomotor and can make two stations rotate for 180° in parallel for the station exchange; The feeding and blanking can be operated manually or by manipulator at the fixed position.

The servo mechanism is driven by the precise servo motor and reducer and can make the work piece overturn in the vertical direction and stay at any circumferential direction position in order to obtain the best welding position.

Flexible welding solution

LAG owns the automation service experience for many years, and can customize various individual welding solutions for users as per the customer factory.

Related products